Cocoa powder has a strong taste and is an indispensable ingredient for making ice cream, drinks, cakes, desserts and other delicacies. Cocoa powder is closely related to our life. So do you know how cocoa powder is made? How did cocoa powder come from cocoa beans?

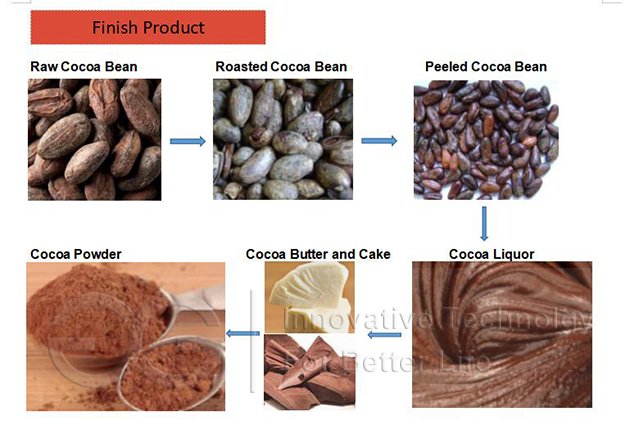

Cocoa powder is the seeds taken from the fruit of the cocoa tree, that is, cocoa beans. After cocoa beans are fermented, coarsely crushed, peeled and other processes to obtain cocoa cakes, the cocoa cakes are degreased and crushed to become cocoa powder, cocoa powder. It has a strong aroma, does not contain cocoa butter, and can be used as a raw material for making food.

We have a complete cocoa powder production line, from raw materials to finished products, you can check the specific production process: Automatic Cocoa Powder Production Line

Some questions about the cocoa powder production line:

1. What are the requirements for cocoa beans when making cocoa powder?

Cocoa beans have been fermented. It needs to be relocated and classified, and the water content needs to reach 5-7% after roasting. The normal roasting temperature is 120 °C.

2. What percentage of cocoa beans can produce cocoa powder, cocoa liquor, and cocoa butter?

The weight of ground cocoa liquor = the weight of cocoa beans after roasting * 98%; the cocoa butter ratio is 40-45%, and the rest is cocoa powder. Generally, cocoa butter is pressed with a hydraulic oil press. After the cocoa butter is cooled, it is a white solid, that is, cocoa butter.

3. What is the difference between natural cocoa powder and alkalized cocoa powder?

Natural cocoa powder is a powder obtained by defatting and grinding without any additives. The pH value is 5.4-5.7 and it is acidic. Mainly used for the processing of natural chocolate and other foods. Alkalized cocoa powder is a powder obtained by degreasing and grinding after acidification, and is neutralized. In the process of cooling and stirring, edible alkali is added, and the pH value is 6.8-7.2. It is mainly used for the processing of chocolate beverages and is not suitable for the production of chocolate.

More details please contact me freely, we will arrange our customer manager to send you the machine price.

Contacts: Cara

Email:cara@machinehall.com

Tel:0086-13015518550

More details please contact me freely, we will arrange our customer manager to send you the machine price.

Contacts: Cara

Email:cara@machinehall.com

Tel:0086-13015518550